For MAE 2250, Cornell’s design & manufacturing class, I worked in a group of 7 to produce a working water pump, whose objective was to pump 1L of water per minute.

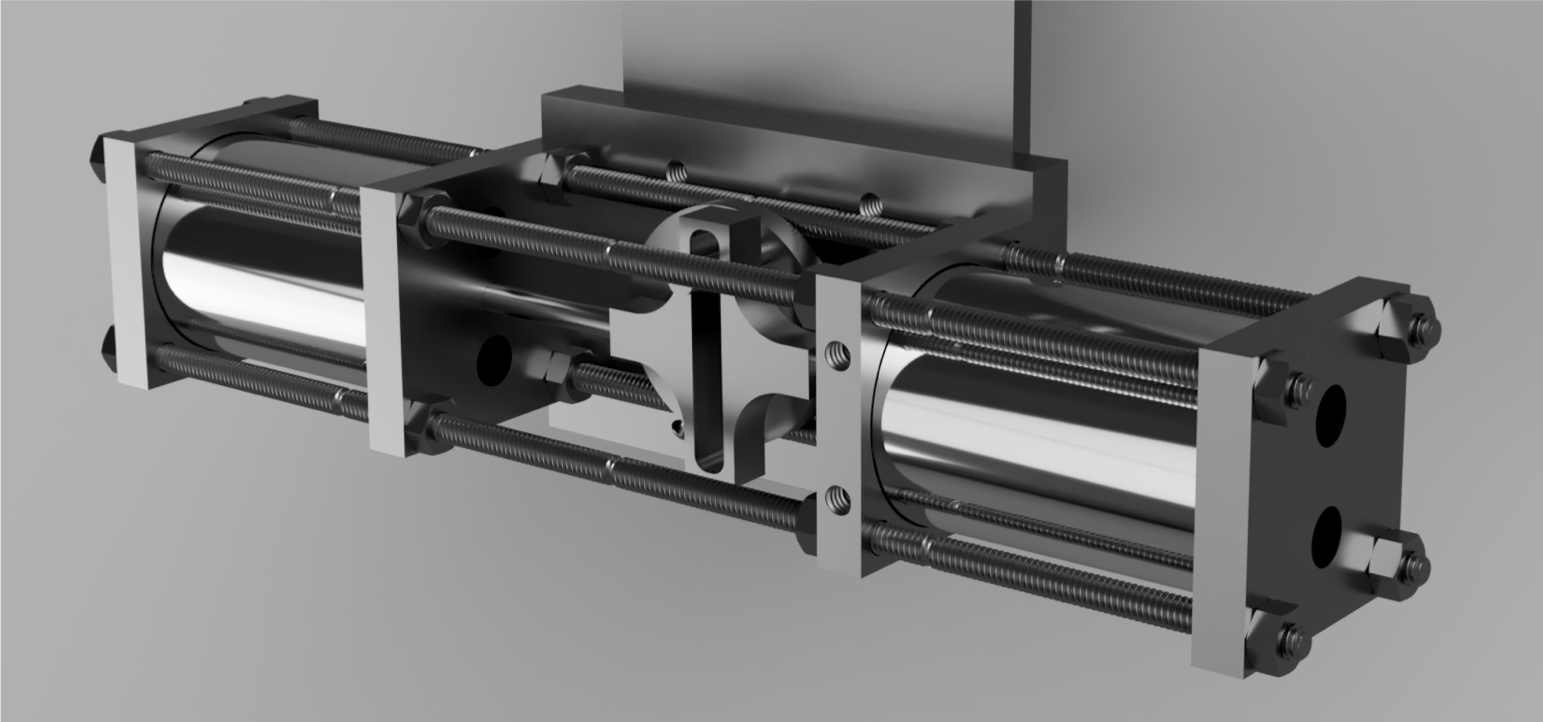

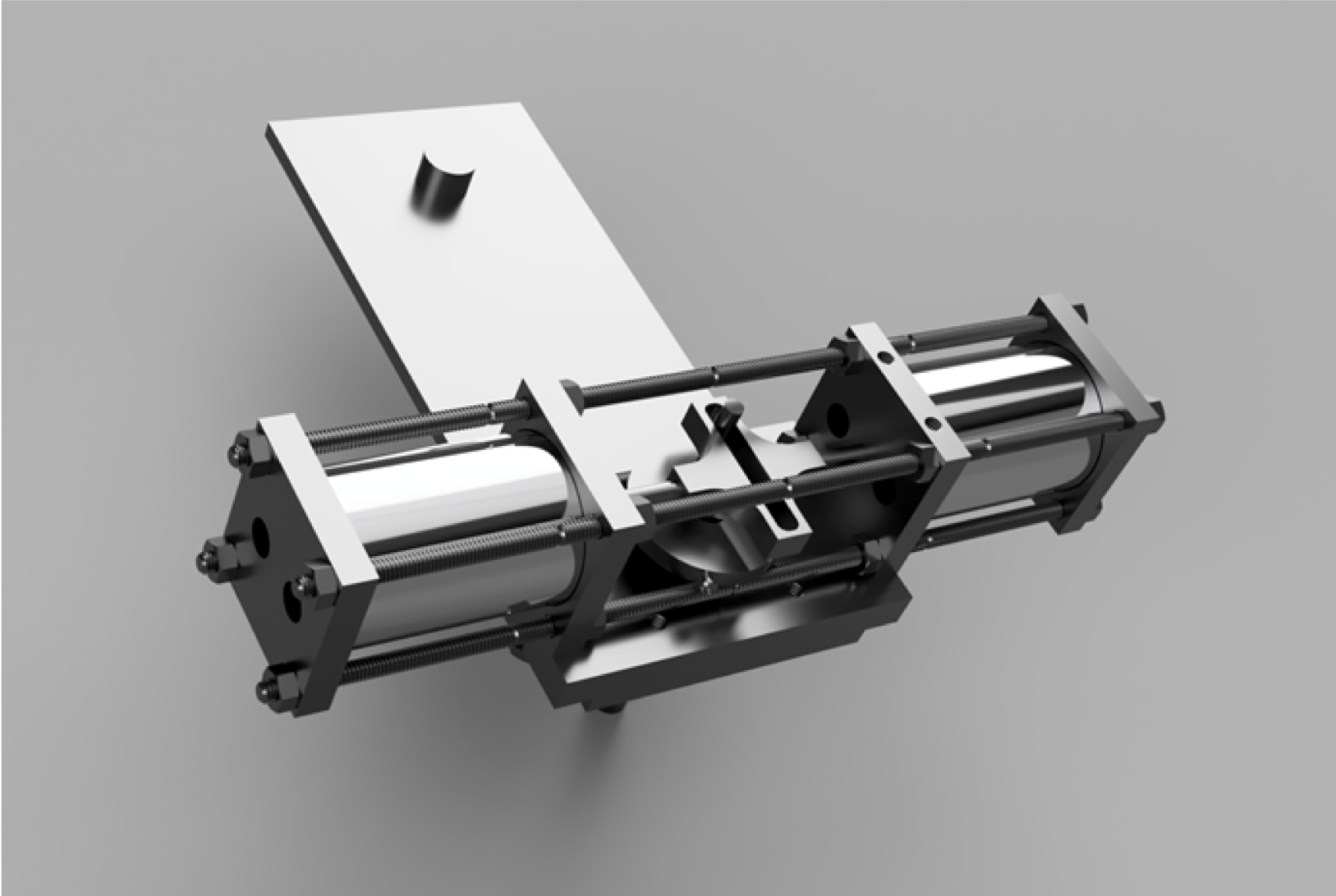

My responsibility in the group was the design of the pump. The design chosen was a double piston pump with a scotch yoke, which presented unique issues requiring careful material and mechanism selection. My role also included created and maintaining the CAD model, in Autodesk Fusion 360. This required quick learning of a CAD package I hadn’t used before.

The project also allowed me to develop important non-technical skills: holding regular meetings to ensure everyone had a clear role in the project and everyone’s ideas were listened to, ensuring the schedule was on track, and working out logistics for mass production within a budget.

Our water pump was able to pump almost 7L in a minute, below are some pictures of the pump and CAD renders, and here is our technical report.

![]()

![]()

![]()

My responsibility in the group was the design of the pump. The design chosen was a double piston pump with a scotch yoke, which presented unique issues requiring careful material and mechanism selection. My role also included created and maintaining the CAD model, in Autodesk Fusion 360. This required quick learning of a CAD package I hadn’t used before.

The project also allowed me to develop important non-technical skills: holding regular meetings to ensure everyone had a clear role in the project and everyone’s ideas were listened to, ensuring the schedule was on track, and working out logistics for mass production within a budget.

Our water pump was able to pump almost 7L in a minute, below are some pictures of the pump and CAD renders, and here is our technical report.

To comply with ITAR regulations and NDAs, all Astranis, Blue Origin, Northrop Grumman and SpaceX pictures shown are available publicly online