Coffee Tamper

Spring 2018

Spring 2018

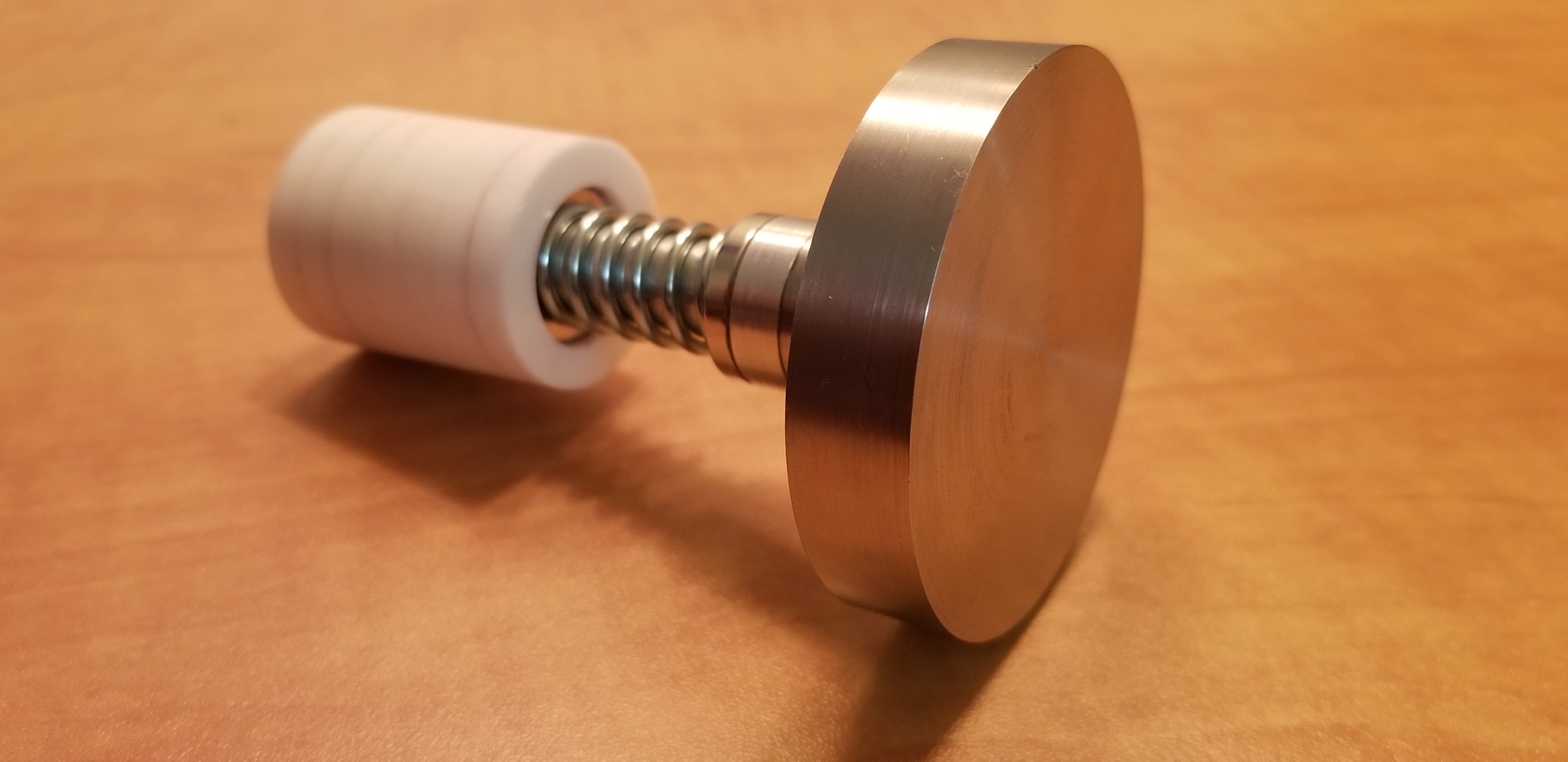

For my final project in Cornell’s mechanical design & manufacturing class MAE 2250, I worked with Zac Capel to design and prototype a product for use in a commercial kitchen. We chose to design a coffee tamper. This is a device used by baristas brewing espresso to compress coffee granules before pressurized hot water is passed through, producing the drink. The issue faced by many trainee baristas is that judging the correct tamping force is difficult without some kind of feedback.

Our product solved this issue in an inexpensive way, by using a spring to provide mechanical feedback to the user when the correct tamping force is applied. We also ensured our design was modular to allow the handle to be swapped for baristas to personalize their own tampers.

The project had a tight budget to produce the prototype, which made it important to select our materials carefully while ensuring we would not be restricted by our manufacturing processes. I learned about prototyping and the design cycle, as well as designing for manufacturability and mass production.

The product received an award for “Best Open Design Project” and we presented it to the class. Below is our promotional video for Espresso Compresso, along with some images of the product from throughout the project, and here is our final presentation.

![]()

![]()

![]()

![]()

![]()

Our product solved this issue in an inexpensive way, by using a spring to provide mechanical feedback to the user when the correct tamping force is applied. We also ensured our design was modular to allow the handle to be swapped for baristas to personalize their own tampers.

The project had a tight budget to produce the prototype, which made it important to select our materials carefully while ensuring we would not be restricted by our manufacturing processes. I learned about prototyping and the design cycle, as well as designing for manufacturability and mass production.

The product received an award for “Best Open Design Project” and we presented it to the class. Below is our promotional video for Espresso Compresso, along with some images of the product from throughout the project, and here is our final presentation.

To comply with ITAR regulations and NDAs, all Astranis, Blue Origin, Northrop Grumman and SpaceX pictures shown are available publicly online