Astranis

Internship, Spring 2021

Full Time, Fall 2021 - Spring 2022

Internship, Spring 2021

Full Time, Fall 2021 - Spring 2022

I joined Astranis as an intern in Spring 2021, eventually converting to a full time employee in Fall 2021, spending about a year working across a variety of interesting spacecraft projects.

A large initial project was developing a center of gravity measuring scale for our spacecraft, to accurately locate to within 5mm. This involved design in Solidworks, analysis in ANSYS, and writing build and operation instructions, as well as testing out the scale to verify accuracy.

Another project was design of a heater system to keep the unpowered spacecraft warm on the Falcon Heavy second stage on its coast to final Geosynchronous orbit, including a lot of mechanical design and design reviews internally and with our launch provider SpaceX. I also helped to maintain the Interface Control Document (ICD) with our launch provider.

I was responsible for designing our TVAC Payload Test, which involved sizing and procuring RF hardware, working closely with the payload and thermal teams to define requirements and ensure the test setup met space, cost, and assembly constraints.

When I joined back as a full time employee, I owned the mechanical side our Gyroscope system, working closely with the GNC and Avionics teams to ensure my hardware design met sensing, thermal, and assembly requirements. I also worked closely with technicians to ensure the system could be easily and repeatably built, where I relearned an important lesson about always prioritizing technician feedback on a design. This also led to co-owning development of a section of the spacecraft factory, which would be used for mass-building electronics enclosures. Again, it was critical to work closely with technicians and Assembly, Integration and Test engineers to ensure the factory met their build needs.

My final main project revolved around design of our smaller Deployable Splashplate Antenna. I was responsible for mechanical design and packaging of the deployment mechanisms and composite structures. The pointing requirements for this system were very tight, and so it was important to work closely with the Antenna and GNC teams to ensure my design would meet our pointing budget. This involved a mix of studying possible low frequency (launch) and high frequency (thermal) biases that would cause mispointing, and developing a repeatable procedure for aligning the antenna when the system was build. Finally, I characterized these shifts using a mix of lasertracker data and analyzing our models for our GNC team to use in Monte Carlo simulations, so we could conclude our design would meet antenna requirements.

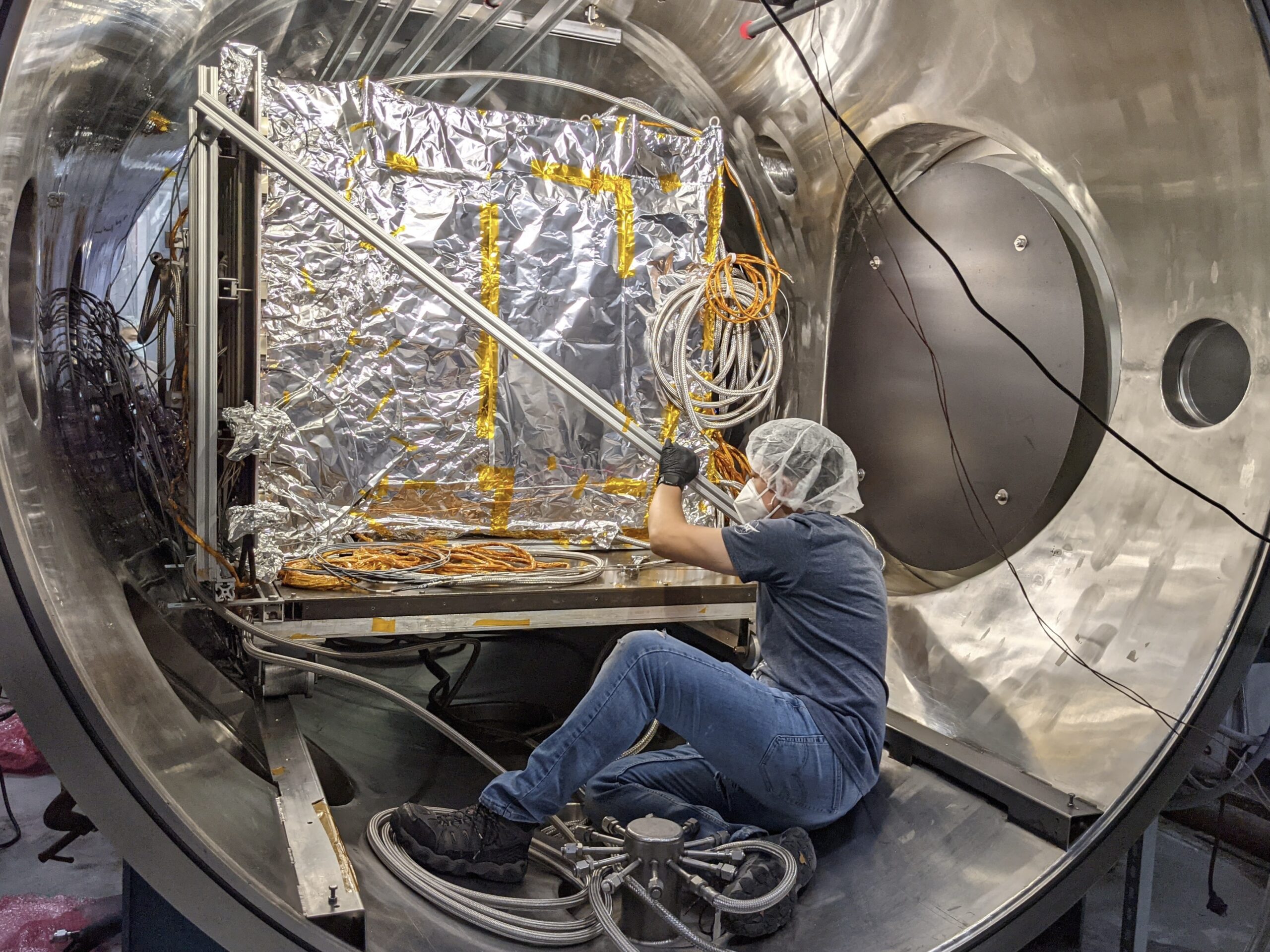

Since these efforts were R&D and Astranis spacecraft are largely in their development phase, below are some public pictures from testing and a recent render.

A large initial project was developing a center of gravity measuring scale for our spacecraft, to accurately locate to within 5mm. This involved design in Solidworks, analysis in ANSYS, and writing build and operation instructions, as well as testing out the scale to verify accuracy.

Another project was design of a heater system to keep the unpowered spacecraft warm on the Falcon Heavy second stage on its coast to final Geosynchronous orbit, including a lot of mechanical design and design reviews internally and with our launch provider SpaceX. I also helped to maintain the Interface Control Document (ICD) with our launch provider.

I was responsible for designing our TVAC Payload Test, which involved sizing and procuring RF hardware, working closely with the payload and thermal teams to define requirements and ensure the test setup met space, cost, and assembly constraints.

When I joined back as a full time employee, I owned the mechanical side our Gyroscope system, working closely with the GNC and Avionics teams to ensure my hardware design met sensing, thermal, and assembly requirements. I also worked closely with technicians to ensure the system could be easily and repeatably built, where I relearned an important lesson about always prioritizing technician feedback on a design. This also led to co-owning development of a section of the spacecraft factory, which would be used for mass-building electronics enclosures. Again, it was critical to work closely with technicians and Assembly, Integration and Test engineers to ensure the factory met their build needs.

My final main project revolved around design of our smaller Deployable Splashplate Antenna. I was responsible for mechanical design and packaging of the deployment mechanisms and composite structures. The pointing requirements for this system were very tight, and so it was important to work closely with the Antenna and GNC teams to ensure my design would meet our pointing budget. This involved a mix of studying possible low frequency (launch) and high frequency (thermal) biases that would cause mispointing, and developing a repeatable procedure for aligning the antenna when the system was build. Finally, I characterized these shifts using a mix of lasertracker data and analyzing our models for our GNC team to use in Monte Carlo simulations, so we could conclude our design would meet antenna requirements.

Since these efforts were R&D and Astranis spacecraft are largely in their development phase, below are some public pictures from testing and a recent render.

To comply with ITAR regulations and NDAs, all Astranis, Blue Origin, Northrop Grumman and SpaceX pictures shown are available publicly online